- Overview

- Product Description

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Custom Sheet Metal Fabrication Electronic Device Instrument Shell Electronics Enclosure Part

Custom Precision Sheet Metal Fabrication Parts | |

Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

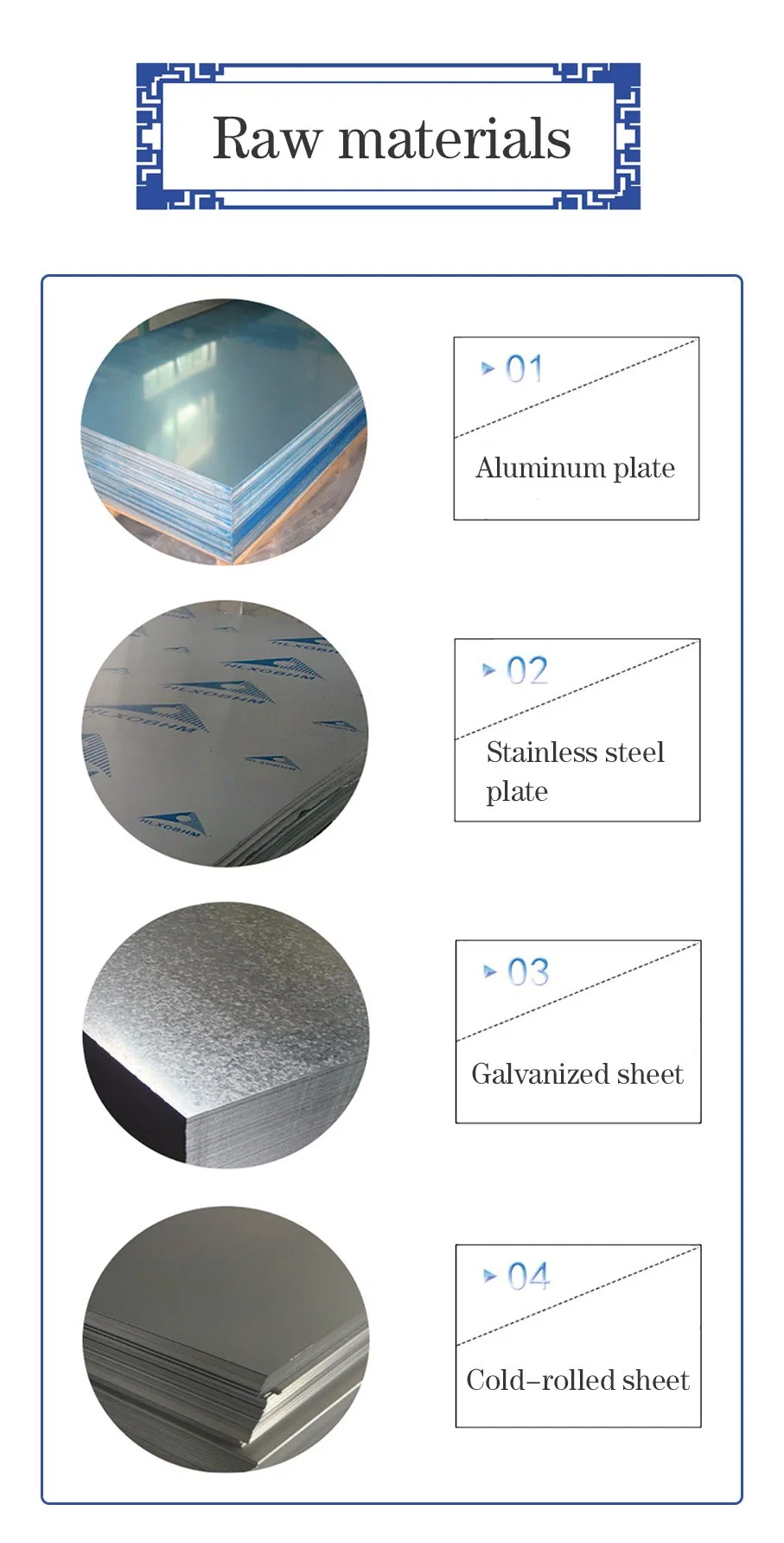

Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

Processing | Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding etc |

Surface Treatment | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

Tolerance | +/-0.2mm, 100% QC quality inspection before delivery, can provide quality inspection form |

Logo | Silk print, Laser marking. |

Size | Accept custom size. |

Color | White, black,silver, red, grey, Pantone and RAL, etc |

Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. |

Sample lead time | No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

Pricing Term | EXW, FOB, CIF, etc |

Payment term | Sample: 100% payment before production Mass production: (50% in advance as deposit, balance before delivery) |

Certificate | ISO9001:2015/SGS/TUV/RoHS |

Packing | By carton or as your request |

Our Service

1) OEM service

2) Own factory to offer the reasonable prices and quick response.

3) One-to-One after sales services,answer question for customers 24 hours every day

4) Experienced project team,each product is tracked by a specially assigned person

1. Item: electric metel box

1. Item: electric metel box 2. material: aluminum/stainless steel

3. surface treatment: electroplating

4. tolerance: +/- 0.1mm

5. process: sheet metal fabrication

6. certificate: ISO 9001: 2008, SGS, Rohs.

(1) This sheet metal products is our customed made stamping parts, it's processed by

(1) This sheet metal products is our customed made stamping parts, it's processed bypunching machine through stamping tooling, the subsequent process of the staming product

make of sheet metal is finished by tapping, debur, chamfer, riveting, anodised, packing, the

OEM metal stamping products, sheet metal bracket can be used as medical instruments,

medical apparatus hardware mounting brackets.

(2) We are a professional metal manufacturing factory for sheet metal parts, stamping

parts is our featured product, we are specilizing in designing and manufacturing all kinds of

high quality stamping product made of sheet metal, we have a lot of advanced equipments

and a nice team who can use solidworks, CAD etc, professionally to produce sheet metal

precision stamping products.

(3) Any OEM/ODM are available! We have 13 years professional experience of metal

especially for sheet metal products, metal stamping parts and CNC parts manufacturing,

hardware accessories.

(4) Before mass production, we offer pre-production samples of the sheet metal fine

stamping product and all other sheet metal stamping parts for customer final confirmation.

Quality control:

Quality control:*We have specialized QC testers to check the quality of the products according to different customers' requirement. Usually, it's random inspection, and we also offer 100% inspection at a reasonable price if required.

*We have IQC to check the dimensions and surface of the incoming material

*We have PQC to inspect full-course during the manufacturing processing

*We have FQC to inspect all the anodizing/plating and other finishes' products from our supplier and proceed with the professional quality and appearance inspection before shipping.

Shipping way:

Shipping way:1) 0-100kg: express&air freight priority,

2) >100kg: sea freight priority,

3) As per customized specifications

Packing & Delivery:

1.Packing Detail: The product packed in bag, carton, wood case, pallet or as per the customer's special requirements. Besides, the custom package takes a week to prepare in advance.

2.Delivery Detail: the fast International Shipping time takes 3 ~5 working days by DHL/UPS/FedEx, slow shipping time takes 7~ 8 working days by DHL/UPS/FedEx/TNT, etc

FAQ

Q1: Are you a trading company or a factory?

A: We are a manufacturer specialized in producing OEM parts.

Q2: Do you accept to manufacturing customized products based on our design?

A: Yes, we are a professional factory with an experienced engineering team, would like to provide the OEM service.

Q3: How can I get the quotation?

A: We will offer you the quotation within 24 working hours after receiving your detailed information. In order to

quote you faster and more accurate, please provide us the following information together with your inquiry:

1) CAD or 3D Drawings

2) Tolerance.

3) Material requirement

4) Surface treatment

5) Quantity (per order/per month/annual)

6) Any special demands or requirements, such as packing, labels, delivery,etc.

Q4: Will my drawings be safe after sending them to you?

A: Sure, we will keep them well and not release to others without your permission.

Q5: How long is the lead-time for sample and Bulk production?

A: Normally, the lead time for samples is around 3-4 weeks, for bulk production is around 5-8 weeks (depends

on order quantity)

Q6: Is it possible to know how are my products going on without visiting your factory?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which

show the machining progress.

You can look through our website to find your interest or email your any questions

through below approach! We will reply to you within 12 hours.